IMPELLER SHEAR Pumps

Zeutech has been in the forefront in designing, manufacturing and supplying advanced shear pumps from last 25 years. Being veterans in manufacturing pumps, we have created and propagated mixing solutions from a truly unique perspective that revolutionized mixing, homogenizing, dispersing applications in dairy, beverages, food processing and many other industries. Mixing and pumping in single unit is certainly an advantage for variety of applications that require both pumping and mixing inline or in a single pump. Zeutech Shear Pump with impeller model certainly is an advantage for many such industries and applications which require cost effective and performance based solutions for their pumping and mixing needs.

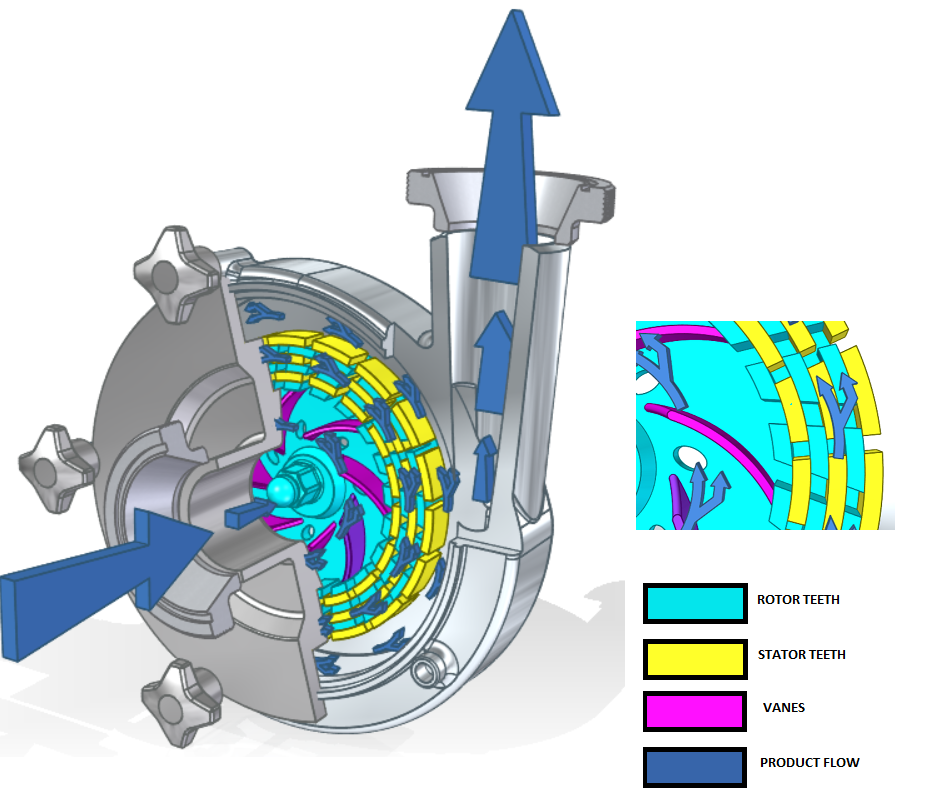

The significant difference between Zeutech Full Shear Pump and Impeller Shear Pump versions is that the impeller of full shear pump version is entirely rotor-stator design aiming for maximum mixing even though the product transfer happens, the full shear pump offers a very low differential head. Where as in Zeutech Impeller Shear Pump, the magical combination of rotor-stator and vanned impeller offers a high differential head or discharge head along with mixing. This means the product transfer is much better and more efficient in the impeller shear pump than the full shear pump.

Our Shear Pumps are innovative, efficient, advanced and sophisticated centrifugal type pumps which are designed ideally for sanitary applications be it in dairies, food processing, pharmaceuticals, beverages, breweries etc. The very basic difference between a normal centrifugal pump and shear pump is the design and construction of impeller. The Shear Pump uses an intermeshed rotor and stator system of impeller to disperse particles into liquid. Zeutech offers a modern range of shear pumps which are systematically aimed at the mixing and pumping tasks of users. More than 25 years of extensive experience coupled with advanced cutting-edge technology and precise engineering calculations has made us the leading shear pump manufacturer and exporter.

Application: Dairies, beverages, food processing, breweries, fruit-based drinks, chemicals, pharmaceuticals, paints, dyes, pigments, biotechnology, cosmetics and personal care, chemicals, paper and cellulose, effluent treatment, water treatment plants and many other industries where mixing applications are in place.

Every aspect of our shear pumps like selection of use of suitable material for construction, design of impeller, rightly rated motors, etc. are taken in greatest care to provide the users optimum benefits like higher performance, lower power consumption, reduction of operation time, product safety, low operational running cost, minimum human intervention, error free operation, environmental savings etc.

Zeutech shear pumps operate successfully worldwide due to its extensive and sophisticated technology for all hygienic, sanitary and non-sanitary industrial pumping applications. What stand out in case of Zeutech Shear Pumps are: high levels of safety and hygiene for hygienic application, superior performance, reliable and efficient product handling, durable and sturdy construction, flawless design, unmatched after-sales service etc., all these in a very affordable pricing.

High discharge head – the extra mile

In Zeutech Impeller Shear Pump, the magical combination of rotor-stator and vanned impeller offers a high differential head or discharge head along with mixing. This means the product transfer is much better and more efficient than the full shear version. High discharge head enhances the usability and practicability of the impeller shear pumps for liquid transport and mixing.

Combined mixing with pumping

Inline mixing is certainly the biggest advantage that our shear pumps offer to the users. Shear pumps combine product transfer with uniform mixing or dispersing the product during the transfer helps in reducing process time and effort while improving the product quality.

Optimum performance

Zeutech shear pumps are renowned for their high efficiency, low energy consumption, 100% hygienic, extensive customization levels, and a wide range of duty parameters for handling various liquids of different viscosity ranges. Zeutech Shear Pumps for blends product quickly and consistently compared to conventional method thus helps in shortening processing duration significantly.

The shear pump’s rotor-stator design eliminates unblended products and prevent lumps and masses in product for consistent, repeatable results.

Our perfected shear pump offers the following broad advantages

- • Improves product texture

- • Reduces processing time

- • Economical to operate and maintain

- • Low maintenance design for continuous duty

- • CIP / SIP compatible

Rotor-stator with vane impeller

The Shear Pump uses an intermeshed rotor / stator system to disperse particles into liquid or emulsifying the liquid. The rotating teeth pass within 0.5 mm of the stationary teeth at high speeds, causing a tremendous amount of turbulence. As centrifugal force pushes the product towards the outlet, the intensity of this turbulence ensures that all products must be thoroughly blended to exit the Shear Pump. The presence of vane impeller in the middle of the impeller improves the creation of kinetic energy to the fluid which in-turn gets transported with a certain discharge pressure.

Eight missions – one machine

The Zeutech shear pumps deliver paramount performance and provide maximum benefit to the use by doing seven tasks effortlessly, these seven tasks are

- 1. Product transfer – the presence of vane impeller in the middle of the impeller improves the creation of kinetic energy to the fluid which in-turn gets transported with a certain discharge pressure.

- 2. Mixing – ensures product mixing or dissolution of soluble solids in solvent, becomes the predominant constituent in sugar dissolving system or powder blender where inline mixing and solution is the key factor.

- 3. Blending - provides continuous, inline blending without air incorporation or formation lumps of dry product resulting in very uniform blending.

- 4. Texturing - gives a smooth body and texture to many products like buttermilk, yoghurt, Laban, tomato sauce/puree or other food pastes etc. Use of various impeller rotor/stator combinations and/or adjustment of rotor speed provide precise control of texturizing effect.

- 5. Reconstitution - assists reconstitution of powdered products, such as milk powders or SMP. Recirculation with Shear Pump provides faster and more complete solution.

- 6. Homogenizing – creates homogenization effect to a greater degree in the liquid stream by continuous rotation of impeller which has the teeth of very low clearances.

- 7. Emulsifying - makes stable emulsions of products with both oil and water base ingredients with the help of high shearing effect of its rotor and stator designed impeller. The requirements for stabilizer and/or emulsifier additives may be reduced due to the tremendous turbulence effect flowing through very narrow clearances.

- 8. Dispersion - helps in creating stable solids in liquid suspensions by uniform dispersion of the solid particles in the liquid stream. Reduction of Particle size too is possible.

Sophisticated flawless design

Zeutech shear pumps are superiorly designed for optimum combined mixing and product transfer with maximum hygiene and minimum energy consumption. Unified and homogenous seal housing design embrace for a single mechanical seal for a wide range of pumps. The Zeutech design principle guarantees high level of efficiency, minimal secondary flow and a flow optimized pumping channel handle the fluid gently and minimize warming. Zeutech shear pumps are solely equipped with distinctive designed open impeller which are unsurpassed in hygienic applications. Customized steel alloys and solid components with minimum wall thicknesses of 6 to 8 mm provide the ideal basis for hassle-free operation.

Sturdy construction

Zeutech Pumps are of distinguished for their sturdy construction. The pumps are of highest quality construction manufactured from stainless steel of various grades. Housing, front cover and impeller are made by precision casting, produced by the 'Lost-Wax’ method or from solid forgings. Both methods of construction offer a guarantee of precision and non-porous surfaces. Every pump has a minimum wall thickness of 8 to 10 mm, providing a working life-cover of over 25 years. Hundreds of thousands of units have proved themselves on numerous installations.

Hygiene uncompromised

The product contact parts of entire construction are sanitary and 100% hygienic. Made of high grade stainless steel (SS 304, SS 316, SS 304L, SS 316L grades and other food grade materials and components, our entire pump is contamination free and devoid of any pathological threat. Due to its open-impeller design the Zeutech shear pump is easy to clean and fully compatible and works in-sync with cleaning-in-place (CIP).

Mechanical shaft seals: the perfect sealing arrangement

Zeutech shear pumps are equipped with mechanical seals, which we consider as the perfect sealing arrangement for such pumps for varied reasons. Our mechanical seals are designed and manufactured in-house with latest cutting edge technology and advanced facilities for maximum performance with prolonged life. Depending upon the characteristics of the pumping liquid, we make mechanical seals with suitable material of construction for optimum use. Use of premium materials like tungsten carbide, carbon, silicon, Vinton, EPDM etc. makes our mechanical seals perfectly fit to resist in leak which keeping the performance and hygiene intact.

One seal – many pumps

What we mean by saying ‘one seal-many pumps’ is that we have standardized the design of our pumps and mechanical seals in such a way that a certain sized mechanical seal can be used for a wide range of Zeutech shear pumps. It greatly reduces the time, effort and confusion in managing inventory and handling the maintenance.

maintenance and clean ability

Our entire design and construction is aimed for high performance, superior hygiene and easy in cleaning and maintenance. Our high-quality design enables quick and easy replacement of mechanical seals, gaskets, O-rings, shafts or impellers, providing more uptime with lower maintenance costs. The dismantling of the parts and reassembling of the pump spares are extremely easy and unambiguous.

Energy efficient, economical and less operation cost

Zeutech centrifugal shear pumps are economical to own and the operation cost is also very less. The energy efficient motor drastically reduces the power consumption. The main drivers of the pumps are energy efficient induction electric motors of IE2 or IE3 standard which are renowned for their ability to consume less energy. We incorporate the best and renowned branded electrical motors available in the spectrum. Perfectly engineered pumps with unique impeller design are suited to assist in consuming less energy while keeping its higher performance intact.

Low vibration and noise level

The extremely low-vibration running of the Zeutech pumps supports the high reliability and long life of the pumps and the mechanical seals.

Working with low NPSHr is a boon

Our Zeutech shear pumps designed to work with low NPSHr (Net Positive Suction Head required) level are just a boon in pumping application.

Customization to suit the need best

Our custom built pumps are available in a wide capacity ranges for a single pump model to ensure the best fit to the customers’ need and processing requirements. Based on the product and its characteristics and the desired product mixture, we can deliver suitable pump with various construction material options. Pumps with different mounting options, with or without shroud etc. are some of the striking customization features we offer.

Available explosion-proof application

Apart from sanitary applications, we also manufacture the shear pumps for explosion proof application. To achieve this, our pumps are equipped with high quality flame proof electrical motors that are standardized with the competent authorities as per the local governing law.

One pump, varied application

Dairy

- Milk reconstitution

- Milk stabilization

- Chocolate milk

- Cottage cheese dressing

- Ice cream Mix

- Yogurt

- Sour cream

- Eggnog

- Pudding

Bio-pharmaceutical

- Tablet coatings

- Cough syrup

- Topical ointments

- Lotions

- Vitamin drinks

Non-Sanitary

- Biodiesel

- Paintballs

- Fertilizer

- Beverage

- Orange juice

- Mineral water

- Green tea

- Vegetable juice

Food

- Olive oil and water emulsion

- Salsa and hot sauce

- Ketchup and mustard

- Vegetable oil refining

- Mayonnaise

- Salad dressing

- Pizza sauce

Thickeners

- Pectin

- Carbopol

- Carrageenan

- Starches

- Gelatine

- Xanthan Gum

Personal Care

- Shampoo & Conditioner

- Toothpaste

- Lotion & Cream

- Mouthwash

Ingredients

- Skimmed Milk Powder (SMP), Sugar, Ice-cream Mix

- Aloe Vera, Aspartame, on-Fat Dry Milk (NFDM)

- Beeswax, Calcium Carbonate, Salt

- Sodium Citrate, Chocolate Powder, Citric Acid

- Vanilla, Crystal Sugar, Vegetable Oil

- Egg Powder, Whey Protein Concentrate

Quality uncompromised

Our uncompromising stand on quality, hygiene and sanitation, robust and durable construction, incorporating high-end components are the key ingredients to make the unbeatable performer, the advanced shear pumps which gets made in accordance to ISO 9001:2015 standards.

Service and support

With Zeutech Pumps you get 100% quality assurance with unmatched service and round-the-clock support. Our experienced commissioning team provides training and demo sessions to the workmen during commissioning to make them fully capable to run and maintain the pump hassle-free. Our support team makes solutions readily available for any technical issues through multi-channel communications.

Pollution free

The Zeutech shear pump runs without creating noise or any other pollution. These testaments our commitment to clean environment and sustainability policy.

3.jpg)